What are the differences in application scenarios between sanitary grade stainless steel pipes and B

The application scenarios of sanitary grade stainless steel pipes and BA grade stainless steel pipes differ significantly due to differences in hygiene standards, surface treatment, performance requirements, etc. The specific differences are as follows:

1、 Application scenarios of sanitary grade stainless steel pipes

Core requirements: Strict hygiene and cleanliness, anti pollution, corrosion resistance, suitable for fields with extremely high hygiene and safety requirements such as direct contact with food, drugs, medical media, etc.

Typical industries and scenarios

1. Food and beverage industry

Transportation pipelines for liquid foods such as milk, juice, beer, etc. (such as dairy production lines and beverage filling lines).

Storage and transportation equipment for viscous media such as edible oil and sauce.

Steam pipelines and cleaning water systems in food processing equipment (need to be regularly disinfected to avoid bacterial growth).

2. Pharmaceutical and medical industries

Delivery pipelines for medicinal liquids, purified water, and injection water (compliant with GMP standards to avoid drug contamination).

Process pipelines for sterile formulation production lines and vaccine production workshops.

Medical gas pipelines (such as oxygen and compressed air) and surgical instrument cleaning and disinfection equipment in hospital cleanrooms.

3. Cosmetics and daily chemical industry

Storage and delivery pipeline of skin care products, shampoo, perfume and other raw materials (to prevent the reaction between chemicals and pipes from affecting product quality).

Contact type pipelines in cosmetic filling equipment (must meet hygiene certification, such as FDA standards).

4. Bioengineering and Laboratory

Medium pipelines for biological fermentation tanks and cell culture equipment (to avoid microbial contamination of the experimental environment).

Laboratory ultra pure water system, high-precision reagent delivery pipeline.

2、 Application scenarios of BA grade stainless steel pipes

Core requirements: Bright surface, high dimensional accuracy, stable mechanical performance, suitable for scenarios that have certain requirements for appearance and cleanliness, but do not need to meet strict hygiene standards.

Typical industries and scenarios

1. Electronics and Semiconductor Industry

Inert gas delivery pipelines (such as nitrogen, argon, helium) in semiconductor manufacturing are used to prevent impurities from entering the gas and affecting chip production.

Clean gas pipeline for LCD panel production line (requires surface oxidation free skin to avoid particle contamination).

2. Decoration and construction industry

Architectural decorative railings, handrails, and curtain wall support structures (utilizing their bright and beautiful surface effects).

Metal accessories for high-end furniture, kitchen and bathroom equipment (such as stainless steel sink frames, towel racks).

3. Medical devices and equipment

Medical device structural components that do not come into direct contact with the human body, such as medical device casing support tubes and instrument brackets.

Non critical parts in medical gas pipelines (such as compressed air pipelines in general wards, non sterile environments).

4. Instrumentation and Automation Engineering

Pneumatic pipelines and instrument conduits in industrial automation systems (requiring smooth surfaces to reduce gas leaks or impurity blockages).

Transportation of non corrosive media with certain cleanliness requirements in the chemical and petroleum industries (such as instrument air ducts).

5. Other industrial scenarios

Smoke exhaust ducts in kitchen equipment and structural components of commercial kitchen utensils (must be aesthetically pleasing and easy to clean, but do not require food grade certification).

Pre treatment pipelines in water treatment equipment (such as connecting pipes for filtration devices and non potable water contact scenarios).

3、 Comparison and Summary of Application Scenarios

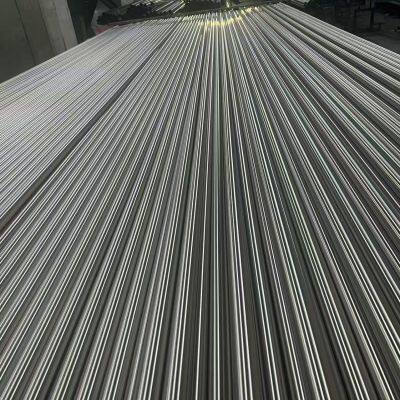

Picture 1

4、 Select logical reference

If the scenario requires "direct contact with food/drugs", "hygiene certification (such as 3A, FDA) is required", or "the medium is prone to bacterial growth", priority should be given to sanitary grade stainless steel pipes.

If the scene focuses on "surface brightness and beauty", "high dimensional accuracy" or "non hygiene sensitive industrial use", then BA grade stainless steel pipes have more cost and performance advantages.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More