How to ensure the service life of stainless steel pipes in medical laboratory gas pipelines?

The service life of stainless steel pipes in medical laboratory gas pipeline systems is affected by various factors such as material selection, processing technology, installation quality, and daily maintenance. From the perspective of full cycle management, the following key measures are provided to ensure the service life:

1、 Source control: optimization of materials and processing technology

1. Strict material selection and certification

Prioritize using 316L stainless steel (containing Mo element, resistant to chloride ion corrosion), and avoid using 304L (slightly weaker corrosion resistance) when transporting high-purity gases or corrosive gases;

Require suppliers to provide intergranular corrosion test reports (such as ASTM A262 E method) and chemical composition analysis certificates to ensure carbon content ≤ 0.03% and sulfur and phosphorus content ≤ 0.03%, and to eliminate inferior recycled materials.

2. High precision surface treatment

The inner wall adopts electrolytic polishing (EP) instead of mechanical polishing, with a surface roughness Ra ≤ 0.4 μ m (high-purity gas pipelines require ≤ 0.2 μ m), reducing the adsorption of impurities and bacterial growth in the gas;

After polishing, nitric acid passivation treatment is carried out to form a Cr ₂ O Ⅲ passivation film with a thickness of 5-10nm. The passivation effect is verified by blue dot testing (no blue dots indicate complete passivation).

3. Cleanliness control before leaving the factory

The pipeline needs to be cleaned by ultrasonic degreasing (using ethanol or acetone as the solvent), and then blown with high-purity nitrogen gas (purity ≥ 99.99%) until there are no visible particles on the inner wall;

The packaging adopts vacuum sealing and moisture-proof paper to avoid dust and water vapor pollution on the inner wall during transportation.

2、 Installation process: eliminate human damage and hidden dangers

1. Standardization of welding process

Automatic TIG orbital welding is adopted, and pure argon gas (flow rate 5-10L/min) is filled inside the tube during welding to protect the inner wall and prevent oxidation and blackening (the oxidation layer will accelerate corrosion);

Each weld seam needs to undergo 100% helium mass spectrometry leak detection (leakage rate ≤ 1 × 10 ⁻¹⁰ Pa · m ³/s) and X-ray inspection to eliminate defects such as virtual welding and porosity.

2. Installation details for corrosion prevention

The pipeline support is made of stainless steel material, and PTFE isolation pads should be added when in contact with the carbon steel support to avoid electrochemical corrosion;

The installation slope should be controlled at 0.5% to 1%, and a stainless steel drain valve should be installed at the concentrated condensate to prevent acidic condensate (such as CO ₂ dissolved in water to form carbonic acid) from long-term retention and corrosion of the inner wall.

3. Special treatment of oxygen pipelines

All pipelines and valves that come into contact with oxygen must pass degreasing certification (wiped with white silk cloth without oil stains). It is prohibited to use tools containing grease for installation to avoid the risk of explosion and damage to the passivation film caused by grease.

3、 Operation and maintenance: dynamic monitoring and preventive maintenance

1. Regular leak detection

Perform quarterly helium mass spectrometer leak detection on welds and joints, with a focus on stress concentration areas such as valves, elbows, and tees;

The sealing of the oxygen pipeline is checked monthly using soap and water application method, and any bubbles found are immediately marked and repaired.

2. Gas purity and monitoring of corrosive media

Online monitoring of the dew point (≤ -40 ℃) and oxygen content (≤ 1ppm) of high-purity gases (such as N ₂, Ar) to avoid corrosion of the inner wall caused by water vapor and oxygen;

When transporting corrosive gases (such as Cl ₂, SO ₂), corrosion sensors should be installed at the end of the pipeline to monitor the gas concentration in real time, and the exhaust system should be linked when it exceeds the standard.

3. Inner wall cleaning and passivation repair

Annually use high-purity nitrogen gas (with 0.1% nitric acid solution) for cyclic purging and passivation to repair minor damage to the passivation film;

If rust spots are found on the inner wall of the pipeline, it needs to be disassembled and re electrolytically polished and passivated. In severe cases, the pipeline section should be replaced.

4、 Environment and System Design Optimization

1. Laboratory environment control

Maintain laboratory humidity ≤ 60% RH to avoid condensation of humid air on the outer wall of the pipeline; If there is acid mist (such as hydrochloric acid volatilization), it is necessary to strengthen ventilation or spray a corrosion-resistant coating (such as Teflon) on the outer wall of the pipeline.

2. System redundancy and segmented control

Design a dual backup system for critical gas pipelines (such as medical oxygen) to facilitate switching during single channel maintenance;

Set cut-off valves according to functional areas, and isolate and repair local pipeline damage to prevent the entire system from being shut down.

3. Anti static and grounding design

When transporting flammable gases (such as H ₂), the pipeline needs to be grounded every 100 meters (grounding resistance ≤ 4 Ω), and copper braided tape should be used to cross the flange connection to prevent static electricity accumulation and breakdown of the passivation film.

5、 Targeted measures for special gases

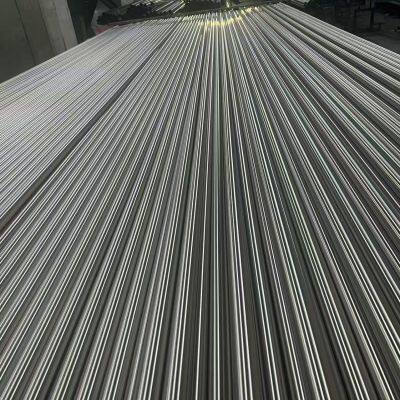

Picture 1

6、 Standardized management and personnel training

1. Establish a full lifecycle archive

Record the material batch number, welding date, inspection report, and maintenance records of each section of the pipeline, and implement traceability management through QR code identification;

According to GB 50751 "Technical Specification for Medical Gas Engineering", a life assessment standard is formulated, and pipelines exceeding 15 years need to undergo comprehensive non-destructive testing.

2. Operator training

Prohibit overpressure operation (working pressure ≤ 80% of design pressure), regularly train on emergency handling of pipeline leaks (such as temporary sealing with special tape);

Maintenance personnel need to master stainless steel surface repair techniques (such as the use of local electrolytic polishing equipment) to avoid secondary damage caused by non professional operations.

summarize

The service life of stainless steel pipes in medical laboratories (usually 10-15 years) needs to be controlled through the full chain of "material process installation maintenance": based on high-purity corrosion-resistant materials, combined with high-precision surface treatment and defect free welding, combined with environmental adaptation design and dynamic monitoring, ultimately achieving long service life and low maintenance cost operation of the system. For critical medical gases such as oxygen and laughing gas, it is recommended to commission a third-party organization to conduct comprehensive non-destructive testing and material aging assessment every 5 years, and replace potential risk areas in advance.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More