Difference in performance between duplex stainless steel pipes and austenitic stainless steel pipe

The performance difference between duplex stainless steel pipes and austenitic stainless steel pipes is due to their different microstructures and alloy compositions. The following comparison is made from core dimensions such as mechanical properties, corrosion resistance, and processability, and combined with typical application scenarios to illustrate:

1、 Comparison of microstructure and alloy composition

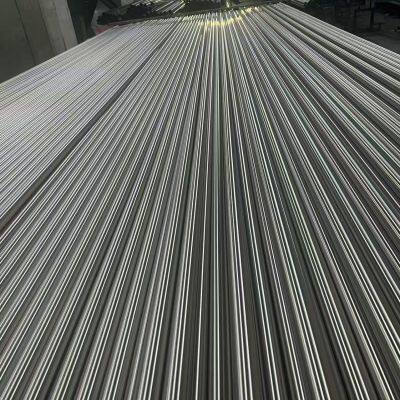

Picture 1

2、 Analysis of core performance differences

1. Mechanical properties: balance difference between strength and toughness

Duplex stainless steel

High strength: Yield strength (σ ₀) ₂) can reach 450-650MPa, which is about twice that of 304 austenitic steel (304 yield strength ≈ 210MPa), due to the "phase boundary strengthening" effect of the two-phase structure; The solid solution strengthening effect of nitrogen (N) (N content 0.15%~0.3%).

Moderate toughness: The room temperature impact toughness (AKV) is about 80-120J, lower than austenitic steel (such as AKV ≈ 200J for 316), but better than ferritic steel.

austenitic stainless steel

Low strength: The yield strength is usually ≤ 300MPa, but the elongation (δ) can reach 40%~60%. It has excellent plasticity and is suitable for deep drawing forming (such as stainless steel tableware).

Super toughness: The impact toughness does not decrease or even increase at low temperatures (such as -196 ℃), making it suitable for liquefied natural gas (LNG) equipment.

2. Corrosion resistance: performance differences in different environments

Duplex stainless steel

Resistance to pitting and crevice corrosion: Due to the synergistic effect of high Cr (22%~26%), Mo (2.5%~5%), and N, the pitting corrosion index PREN (=Cr+3.3Mo+16N) can reach 40-50, significantly better than 304 (PREN ≈ 22) and 316 (PREN ≈ 29), suitable for environments containing Cl ⁻ (such as seawater and chemical saltwater).

Stress Corrosion Resistance (SCC): The two-phase structure reduces the tendency for intergranular corrosion, and the ferrite phase can block crack propagation in austenite. In Cl ⁻ - containing media, SCC resistance is much better than that of austenitic steel (such as 304, which is prone to SCC in seawater environment).

austenitic stainless steel

Corrosion resistance: The Cr Ni passivation film is stable and exhibits excellent performance in environments such as nitric acid and atmosphere, but has weak resistance to pitting corrosion in media containing Cl ⁻.

Risk of intergranular corrosion: If the carbon content (C>0.03%) or heat treatment is improper, Cr ₂ ∝ C ₆ can easily precipitate, leading to chromium depletion. This can be improved by adding Ti, Nb (such as 321) or reducing C (such as 304L).

3. Processing and welding performance: Different process adaptability

Duplex stainless steel

Fast work hardening: During cold forming, the strength rapidly increases while the plasticity decreases. It is necessary to anneal in stages (such as solution treatment at 1050 ℃), otherwise it is prone to cracking.

Welding requires temperature control: The heat affected zone (HAZ) is prone to excessive growth of ferrite or reduction of austenite, leading to a decrease in toughness. Low current, fast welding is required, and no heat treatment is needed after welding (unless the thickness is>30mm).

austenitic stainless steel

Excellent cold formability: low work hardening rate, can be repeatedly bent (such as stainless steel corrugated pipes), and does not require intermediate annealing.

Excellent weldability: Single phase structure is not prone to phase transition stress, and conventional arc welding can be used. Generally, no heat treatment is required after welding (but low-carbon grades such as 316L need to avoid sensitization temperature zones of 400-800 ℃).

4. High temperature and low temperature resistance performance

Duplex stainless steel

Good high-temperature strength: The strength of ferrite phase decays slowly at 500-600 ℃, making it suitable for high-pressure pipelines (such as petroleum refining), but long-term use at temperatures ≤ 300 ℃ (to avoid embrittlement caused by the precipitation of σ phase).

Low temperature toughness is limited: impact toughness begins to decrease below -50 ℃, making it unsuitable for extremely low temperature scenarios.

austenitic stainless steel

High temperature oxidation resistance: 310S (Cr25Ni20) can withstand high temperatures of 1200 ℃ and is commonly used in furnace tubes;

Ultra low temperature advantage: 304L maintains toughness at -196 ℃ and is used for liquid oxygen storage tanks.

5. Magnetism and Cost

Duplex stainless steel

Weak magnetism: The content of ferrite phase determines the strength of magnetism. Due to the equilibrium of the two phases, 2205 has weaker magnetism than pure ferrite steel but stronger than austenitic steel.

High cost: Mo and N content are high, and the smelting process is complex (requiring control of the two-phase ratio), with a price of about 2-3 times that of 304.

austenitic stainless steel

Non magnetic: a single austenitic structure, suitable for magnetic sensitive equipment (such as medical devices).

Cost differentiation: 304 is affordable, 316 is slightly more expensive due to its Mo content, and super austenitic steel (such as 904L) has extremely high costs due to its high Ni Mo content.

3、 Comparison of typical application scenarios

Picture 3

4、 Summary: How to choose?

Prioritize duplex stainless steel: If the requirement is "high strength+Cl ⁻ corrosion resistance+stress cracking resistance", such as in marine engineering and chemical high-pressure pipelines, 2205/2507 is the preferred choice.

Prioritize austenitic stainless steel: If the requirements are "high plasticity+low temperature toughness+non-magnetic+low cost", such as food equipment, low temperature containers, and conventional corrosion-resistant pipelines, 304/316 is more suitable.

The performance difference between the two is essentially a trade-off between "strength corrosion resistance" and "toughness processability", which requires comprehensive decision-making based on working conditions, costs, and process requirements.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More