What is the optimal ratio of each element in duplex stainless steel pipes?

The performance of duplex stainless steel pipes is determined by their unique austenite and ferrite two-phase structure, and the ratio of each element needs to balance the two-phase ratio (usually 40%~60% each), while optimizing corrosion resistance, strength, and processability. The following is the optimal elemental ratio and functional analysis of typical duplex stainless steel pipes (such as 2205, 2507, etc.):

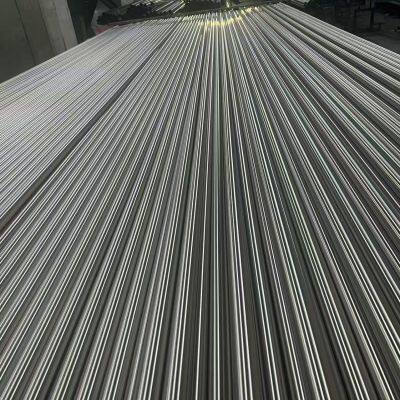

1、 Element ratio of typical duplex stainless steel pipes (taking common grades as examples)

Picture 1

2、 The logic and impact of the ratio of core elements

1. Chromium (Cr) and nickel (Ni): the cornerstone of two-phase equilibrium

Cr: As a ferrite forming element, excessive content can lead to excessive ferrite, making the steel brittle; If the content is insufficient, sufficient passivation film cannot be formed, and the corrosion resistance decreases.

Ni: As an austenite forming element, it needs to be combined with Cr to ensure that the ratio of the two phases is close to 1:1. For example, in 2205, Ni ≈ 5.5% and Cr ≈ 22.5%, the equilibrium can be calculated using the "Ni equivalent" and "Cr equivalent" formulas:

Cr Equivalent (CE)=Cr+Mo+1.5Si+0.5Nb (%)

Ni equivalent (NE)=Ni+30C+30N+0.5Mn (%)

In an ideal situation, CE/NE≈1.0~1.2, To ensure equilibrium between the two phases.

2. Molybdenum (Mo) and Nitrogen (N): The Key to Corrosion Resistance and Strength

Mo: In media containing Cl ⁻ (such as seawater, chemical solutions), Mo can inhibit the initiation of pitting corrosion. 2507 has better corrosion resistance than 2205 due to its higher Mo content (4%~5%).

N: In solid solution form, it not only strengthens austenite, but also synergistically improves pitting corrosion resistance with Mo (pitting index PREN=Cr+3.3Mo+16N, the higher the PREN, the stronger the corrosion resistance). For example:

PREN of 2205 ≈ 40~45, suitable for moderate corrosive environments;

The PREN of 2507 is approximately 45~50, suitable for highly corrosive environments such as marine engineering and petroleum refining.

3. Carbon (C): The lower the better

The carbon content of duplex steel is strictly controlled at ≤ 0.03% to avoid intergranular corrosion caused by Cr ₂ ∝ C ₆ precipitation at high temperatures, which is also an important difference from austenitic stainless steel (such as 304).

4. Manganese (Mn): an economical austenite stabilizing element

The austenite forming ability of Mn is about 1/20 of that of Ni, but the cost is lower. It is commonly used to adjust the two-phase ratio and improve the cold working performance of steel.

3、 Proportion adjustment in different application scenarios

Corrosion resistance priority (such as in marine engineering and chemical equipment): Increase the Mo (4%~5%) and N (0.25%~0.3%) content, such as in 2507 duplex steel.

Strength priority (such as structural components and high-pressure pipelines): increase the N content (about 0.2%), utilize its solid solution strengthening effect, and ensure the two-phase ratio.

Weldability requirements: Reduce the content of C and Si, control Mn below 1.5%, and avoid excessive growth of ferrite in the heat affected zone (HAZ) leading to embrittlement.

4、 Summary: The core principle of optimal ratio

The element ratio of duplex stainless steel pipes needs to meet the optimization of "two-phase balance, corrosion resistance, and strength synergy":

Chromium nickel equilibrium: Control the two-phase ratio by Cr equivalent/Ni equivalent ≈ 1.0~1.2;

Molybdenum nitrogen synergy: Adjust Mo (2.5%~5%) and N (0.15%~0.3%) according to the corrosive environment to enhance the resistance to pitting corrosion;

Low carbon control: C ≤ 0.03% to avoid intergranular corrosion;

Impurity limitation: The lower the content of P and S, the better the toughness and weldability.

The ratio of specific grades needs to be refined based on standards (such as ASTM A240, GB/T 21832) and actual working conditions to achieve the optimal balance between performance and cost.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More