-

Laijing Bu

Hi there! Welcome to my shop. Let me know if you have any questions.

Laijing Bu

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

What are the effects of different elements on stainless steel pipes?

2025-07-15 09:59:50

The performance of stainless steel is mainly determined by the composition and ratio of its alloying elements, and different elements have different effects on the corrosion resistance, mechanical properties, and processing performance of stainless steel pipes. The following is an analysis of the specific functions of common elements:

1、 Core element: Chromium (Cr)

The basis of corrosion resistance: Chromium is a key element for stainless steel to maintain corrosion resistance. When the content is ≥ 12%, it can form a dense passivation film (Cr ₂ O3) on the surface, prevent oxygen and medium from reacting with the substrate, and prevent rusting.

Influence on crystal structure: Improve the ability of steel to form ferrite, and excessive amount may cause the material to become brittle (such as controlling the chromium nickel ratio in ferritic stainless steel).

The comprehensive effect on performance: the higher the chromium content, the stronger the oxidation resistance (such as high temperature corrosion resistance) and acid corrosion resistance, but excessive chromium content will reduce weldability.

2、 Key element: Nickel (Ni)

Stable austenitic structure: Nickel is the main alloying element of austenitic stainless steel (such as 304, 316), which can expand the austenite phase zone, maintain the austenite structure of the steel at room temperature, and improve toughness and ductility.

Enhanced corrosion resistance: Especially in non oxidizing acids (such as sulfuric acid, hydrochloric acid) and alkaline solutions, nickel can significantly improve corrosion resistance and enhance resistance to stress corrosion cracking.

Low temperature performance optimization: Reduce the cold brittle transition temperature of steel to maintain good toughness of stainless steel pipes in low temperature environments (such as steel used in low-temperature storage tanks).

3、 Important alloying element: Molybdenum (Mo)

Resistance to pitting and crevice corrosion: Molybdenum can enhance the stability of passivation films, especially in environments containing chloride ions (such as seawater and salt spray), which can significantly improve the resistance to pitting corrosion (such as 316L containing 2% to 3% more molybdenum than 304).

High temperature resistance and strength: Improve the high temperature strength and oxidation resistance of steel, suitable for high temperature and high pressure working conditions (such as chemical pipelines).

Side effects: Excessive addition can increase the work hardening tendency of steel and result in higher costs.

4、 Controversial element: Carbon (C)

Strength and hardness improvement: Carbon and chromium form carbides (such as Cr ₂ ∝ C ₆), which can significantly improve the strength and wear resistance of steel. However, carbide precipitation consumes chromium in the matrix, leading to a decrease in local chromium content and reducing the risk of corrosion resistance (i.e. "intergranular corrosion").

Control of different steel grades:

Low carbon stainless steel (such as 304L, 316L): carbon content ≤ 0.03%, reduces carbide precipitation, improves weldability and intergranular corrosion resistance.

High strength stainless steel (such as martensitic steel): It is necessary to retain a high carbon content to ensure hardness, but the problem of reduced corrosion resistance needs to be alleviated through heat treatment (such as solution treatment).

5、 Auxiliary elements: titanium (Ti), niobium (Nb)

Resistance to intergranular corrosion: The bonding strength between titanium and niobium and carbon is stronger than that of chromium, and TiC or NbC is preferentially formed to avoid chromium loss due to carbide precipitation. It is commonly used in stainless steel pipes that need to be welded (such as 321, 347).

The impact on performance: A small amount of addition has little effect on mechanical properties, but can significantly improve corrosion resistance, especially suitable for scenarios with high corrosion resistance requirements such as chemical and food industries.

6、 Other common elements

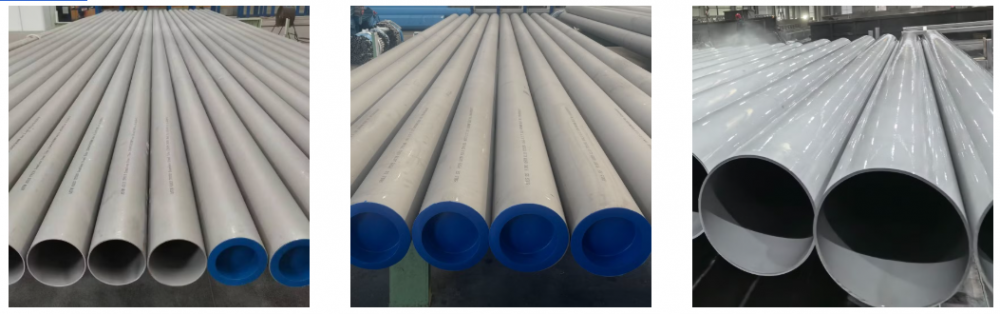

Picture 1

7、 The relationship between element ratio and stainless steel type

Austenitic stainless steel (such as 304, 316): high chromium+high nickel+(molybdenum), excellent comprehensive corrosion resistance and processability, non-magnetic, suitable for food, medical, and construction.

Ferritic stainless steel (such as 430): high chromium+low nickel (or no nickel), low cost, moderate corrosion resistance, magnetic properties, suitable for kitchen utensils.

Martensitic stainless steel (such as 410, 420): high carbon+chromium, high strength but poor corrosion resistance, commonly used in cutting tools and bearings.

Dual phase stainless steel (such as 2205): austenitic+ferritic dual phase structure, high chromium+molybdenum+nitrogen, outstanding strength and corrosion resistance (especially stress corrosion resistance), suitable for marine engineering and chemical high-pressure equipment.

summarize

The performance of stainless steel pipes is the result of the synergistic effect of multiple elements: chromium is the basis of corrosion resistance, nickel determines tissue stability, molybdenum enhances corrosion resistance in special environments, and carbon affects the balance between strength and corrosion resistance. In practical applications, it is necessary to optimize the element ratio according to the working conditions (such as medium, temperature, pressure) and cost requirements, in order to achieve the best balance of corrosion resistance, strength, and processability. For example, pipes used in seaside buildings need to focus on chromium and molybdenum content, while high-pressure pipelines need to balance strength and weldability.

Tags: Core element: Chromium (Cr), Key element: Nickel (Ni), Important alloying element: Molybdenum (Mo)