What requirements are there for stainless steel pipes used in medical oxygen pipelines?

The requirements for stainless steel pipes used in medical oxygen pipelines mainly involve material, specifications, performance, processing and safety, etc., to ensure the safety, reliability and cleanliness of oxygen delivery. The specific requirements are as follows:

I. Material Requirements

1. Stainless Steel Types

Austenitic stainless steel (such as 304, 304L, 316, 316L) is preferred due to its excellent corrosion resistance, oxidation resistance, and non-magnetic properties, which can prevent rust or metal particle shedding during oxygen transportation.

Martensitic stainless steel (such as 410, 420) is prohibited because of its poor corrosion resistance and magnetic properties, which may cause safety hazards in high-pressure oxygen environments.

2. Chemical Composition Control

Carbon content (C): Usually required to be ≤0.03% (such as 304L, 316L) to reduce the risk of intergranular corrosion.

Sulfur content (S) and phosphorus content (P): Must be strictly limited (such as ≤0.03%) to avoid impurities affecting material strength and corrosion resistance.

II. Specifications and Dimension Requirements

1. Pipe Diameter and Wall Thickness

The pipe diameter is determined based on the oxygen flow rate, pressure, and application scenarios (e.g., DN15-DN50 is commonly used in hospital wards). The wall thickness must meet the pressure-bearing requirements and comply with the standards of GB/T 14976 "Seamless Stainless Steel Pipes for Fluid Conveyance" or GB/T 12771 "Welded Stainless Steel Pipes for Fluid Conveyance".

High-pressure oxygen pipelines (such as the main trunk of a central oxygen supply system) should use seamless pipes to ensure strength; low-pressure branch pipes can use welded pipes, but the welds must undergo non-destructive testing (such as radiographic or eddy current testing).

2. Surface Roughness

The inner surface roughness (Ra) of the pipes should be ≤0.8μm, or even ≤0.4μm, to reduce flow resistance and the adhesion of impurities, and to prevent the accumulation of static electricity or the generation of sparks.

III. Performance Requirements

1. Pressure Resistance and Strength

It must meet the design pressure requirements (e.g., the common working pressure of medical oxygen is 0.2-0.6 MPa), and pass the hydrostatic test (test pressure is 1.5 times the working pressure) and pneumatic test to ensure no leakage.

The mechanical properties such as tensile strength and yield strength of the material must comply with relevant national standards.

2. Corrosion Resistance

It must pass the intergranular corrosion test (e.g., GB/T 4334) to ensure no corrosion occurs in humid or oxidizing environments, avoiding rust contamination of oxygen.

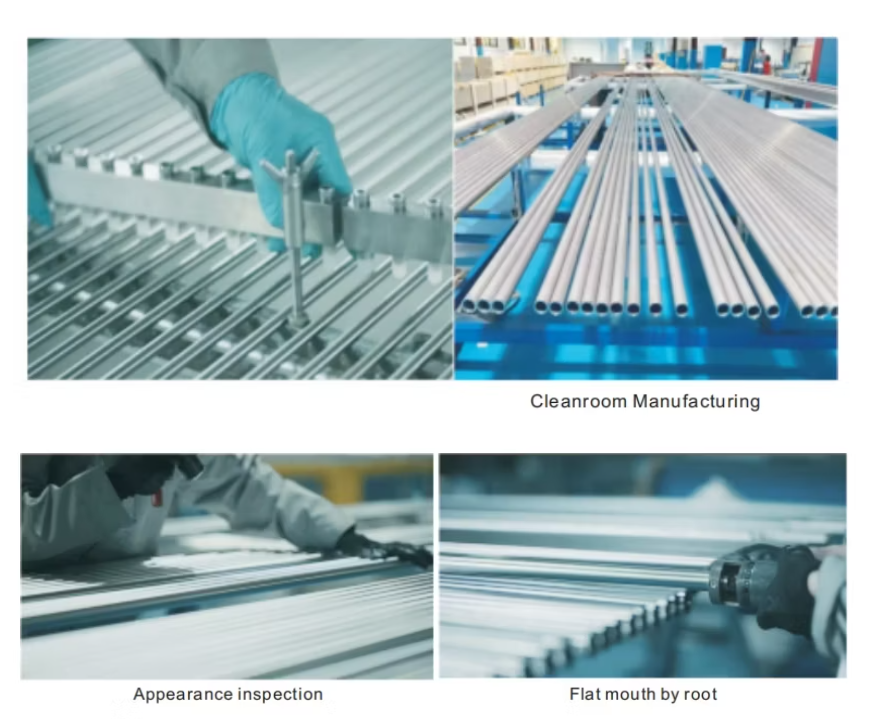

IV. Processing and Manufacturing Requirements

1. Pipe Processing

Cutting: Mechanical cutting or plasma cutting should be used. After cutting, burrs and oxide scales should be removed to avoid debris residue.

Welding: Inert gas shielded welding (such as TIG welding) should be adopted to ensure smooth weld seams without pores. After welding, acid washing and passivation treatment should be carried out to enhance corrosion resistance.

Bending: The bending radius should be ≥ 3 times the pipe diameter to prevent internal wall scratches or deformation.

2. Cleaning and Degreasing

Before installation, strict degreasing treatment (using solvents such as carbon tetrachloride or trichloroethylene) should be conducted to remove oil stains and grease, preventing contact with oxygen which may cause combustion or explosion.

After cleaning, it should be sealed for storage to avoid secondary contamination. During installation, oil-free gloves should be worn for operation.

V. Safety and Installation Requirements

1. Anti-static and Grounding

The stainless steel pipes must be reliably grounded to prevent the accumulation of static electricity generated by the flow of oxygen. The grounding resistance should be ≤ 10Ω. Conductive plates should be bridged at pipe connections to ensure the conduction of static electricity.

2. Marking and Protection

The outer surface of the pipes should be painted blue (the standard color for medical oxygen) and marked with warning words such as "Oxygen" and "No Oil". Protective sleeves should be added when the pipes pass through walls or floors to prevent mechanical damage.

VI. Standards and Certification

It is necessary to comply with national standards (such as GB 50751 "Technical Code for Medical Gas Engineering", GB 150 "Pressure Vessels") and industry norms (such as YY/T 0801 "Seamless Metal Pipes for Medical Gas and Vacuum"). In some scenarios, third-party certification (such as ISO 13485 Medical Device Quality Management System Certification) is required to ensure that materials and processes meet medical requirements.

Summary

For stainless steel pipes used in medical oxygen pipelines, comprehensive control is required from material, processing, performance to safety protection. The core is to ensure the cleanliness and safety of oxygen transmission and avoid medical accidents caused by material defects or contamination. In practical applications, it is necessary to select the appropriate stainless steel pipes in combination with design specifications, usage scenarios and regulatory requirements, and strictly follow the installation standards.

#Knowledge about Stainless Steel Seamless Tubes# #Knowledge about Stainless Steel Tubes# #Stainless Steel [Hot Topic]# #Medical Stainless Steel Tubes#

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More