What requirements do medical oxygen pipelines have for degreased stainless steel pipes?

The requirements for medical oxygen pipelines on degreased stainless steel tubes are extremely strict. They must meet the standards of safety, cleanliness, corrosion resistance and medical application. The specific requirements are as follows:

I. Material and Specification Requirements

1. Material Standards

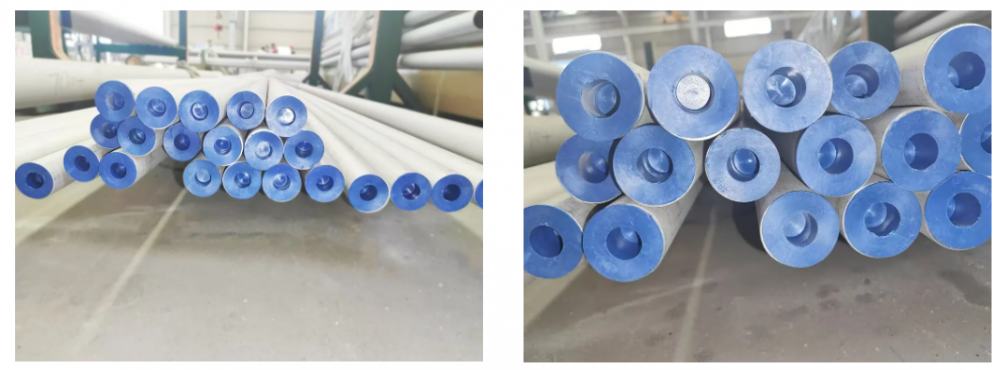

Preferred materials are 316L stainless steel (containing molybdenum, with stronger corrosion resistance) or 304L stainless steel. Avoid using ordinary 304 stainless steel as its high carbon content may cause intergranular corrosion during welding.

The material must meet medical grade standards, such as ASTM A270 (medical grade stainless steel tubes) in the United States or GB/T 14976 (fluid transportation stainless steel seamless tubes) in China, ensuring no heavy metal leaching.

2. Specification Requirements

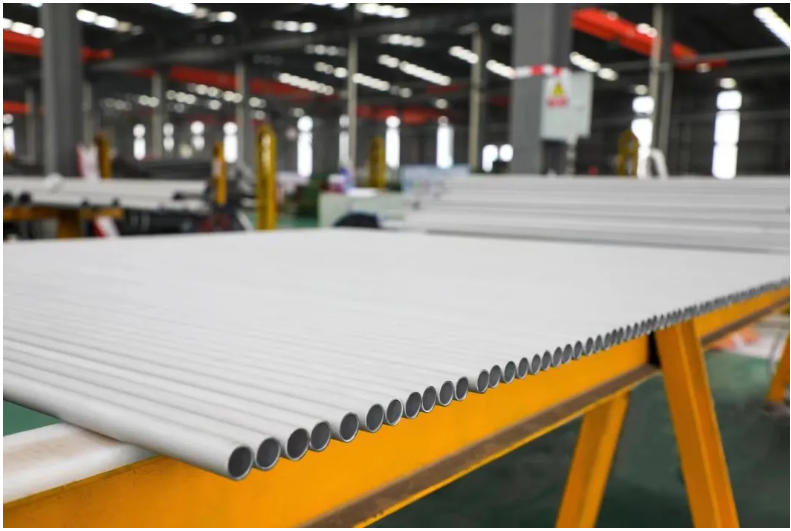

The pipe diameter is designed based on the oxygen demand of the hospital (commonly DN15-DN100). The wall thickness must meet the pressure requirements (usually working pressure 0.2-0.8 MPa), and the inner wall should be smooth (roughness Ra ≤ 0.8 μm) to reduce oxygen flow resistance and impurity deposition.

II. Decontamination Standards

1. Decontamination Process Requirements

Decontamination Method: Use solvent decontamination (such as industrial alcohol, trichloroethylene) or alkaline decontamination. Chlorinated solvents must not be used (as they may corrode stainless steel or leave harmful residues).

Decontamination Procedure

Pre-treatment: Remove visible oil stains, welding slag, etc. from the surface;

Soak in decontaminant or perform cyclic cleaning to ensure complete contact of the pipe inner wall with the decontaminant;

High-pressure pure water rinsing (conductivity ≤ 10 μS/cm), removing residual decontaminant;

Drying Treatment: Use high-purity nitrogen gas (purity ≥ 99.99%) to blow, avoiding residual moisture that may breed microorganisms.

2. Cleanliness Inspection

Oil Residue: Detected by ultraviolet light (no fluorescence reaction on the surface) or by weight method (residue ≤ 50mg/m²).

Particle Pollutants: Inspected by visual inspection or particle counter to ensure there are no visible particles on the pipe inner wall (≥ 5μm particles ≤ 10 per L).

III. Safety and Pressure Resistance Requirements

1. Pressure Resistance and Leakage Test

Pressure Test: A water pressure test is required (1.5 times the working pressure, such as a 0.8 MPa pipeline needs to be tested at 1.2 MPa), maintaining pressure for 30 minutes without leakage; an air pressure test (1.15 times the working pressure) should use high-purity nitrogen to prevent contamination from oil mist in the air.

Air Tightness Test: Use helium mass spectrometry leak detection, with a leakage rate of ≤ 1×10⁻⁹ Pa·m³/s to avoid oxygen leakage that could cause safety hazards (such as possible explosion in the presence of open flames).

2. Anti-static and Grounding

The pipeline needs to be continuously grounded for static electricity (grounding resistance ≤ 10 Ω) to prevent static sparks caused by the high-speed flow of oxygen, and use flange bonding (conductive gaskets) to ensure the conduction of electric charge.

IV. Installation and Welding Requirements

1. Welding Process

Use automatic orbital welding (TIG welding) to avoid the formation of welding slag and oxide scale from manual welding. During welding, high-purity argon gas (purity ≥ 99.99%) is filled in the pipe to protect the weld (to prevent oxidation of the weld seam (the oxide layer may fall off and contaminate the oxygen)).

The weld seam needs to undergo acid washing and passivation treatment to remove the surface oxide film, enhancing corrosion resistance, and the roughness Ra of the weld seam should be ≤ 1.6 μm.

2. Installation Environment Control

The installation process should be carried out in a clean environment (such as a clean workshop or a temporary dust-proof shed). Operators should wear dust-free suits, and tools should be degreased and cleaned to avoid secondary pollution.

The pipe supports should be made of stainless steel to avoid rusting of carbon steel supports and contamination of the pipes. A polytetrafluoroethylene gasket should be used to isolate the support from the pipe to prevent electrochemical corrosion.

V. Hygiene and Certification Requirements

1. Microbial Control

After degreasing, the pipelines need to undergo microbial testing (such as the total bacterial colony count ≤ 100 CFU/m²) to prevent bacterial growth from affecting the purity of medical oxygen.

2. Industry Certification

It is necessary to obtain ISO 13485 (Medical Device Quality Management System) and GMP (Good Manufacturing Practice for Pharmaceuticals) certifications. In some countries, it is also required to comply with FDA (U.S. Food and Drug Administration) or CE (European Union Certification) standards.

VI. Maintenance and Testing Requirements

1. Regular Cleaning

During operation, the pipelines should be purged with high-purity nitrogen gas regularly to remove possible deposits. A degreasing recheck (such as the detection of grease residue) should be conducted every 1-2 years.

2. Condition Monitoring

Install pressure sensors and temperature sensors to monitor the operating condition of the pipelines in real time, to avoid material performance degradation due to overpressure or high temperature.

Summary

For medical oxygen pipelines, the use of degreased stainless steel tubes requires strict control throughout the entire process, including material selection, degreasing process, welding and installation, as well as certification and testing. The core objective is to ensure the purity of oxygen (≥99.5%), prevent safety risks caused by grease, and meet the hygiene standards of the medical industry. Any oversight at any stage could lead to oxygen contamination or safety incidents, so it is necessary to strictly follow relevant norms (such as the "Medical Gas Engineering Technical Specifications" GB 50751 of China).

Recently Posted

-

What are the common defects of stainless steel welding pipes

December 25, 2025Underfilled: The phenomenon where the root of the joint is not fully welded during fusion welding is called underfilled. This defe Read More

Read More -

Introducing the ideal material for fire protection piping system: 304 stainless steel pipe

December 25, 2025In modern architecture, fire safety is of utmost importance. The fire protection pipeline system, as the core component of the fix Read More

Read More -

Why are sanitary-grade stainless steel pipes so important

December 25, 2025In modern industrial production and daily life, the safety and hygiene of pipeline systems are of utmost importance. Hygienic-grad Read More

Read More -

What are the differences between different types of stainless steel water pipes

December 25, 2025In modern architecture and industry, stainless steel pipes have become the preferred pipe material. They have advantages such as c Read More

Read More