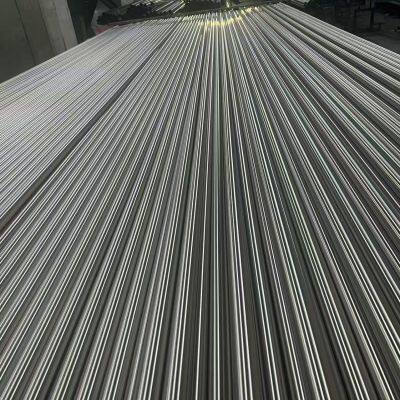

Advantages of stainless steel pipe shot blasting

Shot peening treatment of stainless steel pipes is a process of surface modification achieved by high-speed projectiles (such as steel balls, glass balls, etc.) hitting the surface of the pipe. This process has multiple advantages in the processing and application of stainless steel pipes. The following are its main advantages and analysis:

1、 Improve corrosion resistance

Compressive stress strengthening: Shot peening forms a residual compressive stress layer on the surface, offsetting external tensile stress and delaying the initiation of corrosion cracks.

Surface passivation: Impact damage to the oxide film promotes the regeneration of a dense passivation film (such as Cr ₂ O3) on the surface of stainless steel, enhancing its resistance to pitting and crevice corrosion.

Reduce dirt adhesion: controllable roughness, reduce pollutant retention, indirectly improve corrosion resistance.

2、 Efficient surface cleaning and pretreatment

Removing impurities and oxide layers: Shot blasting can quickly remove impurities such as oxide scale, rust, oil stains, welding spatter, etc. on the surface of stainless steel pipes, especially suitable for pipes after heat treatment (such as solution treatment), restoring the natural color of the metal.

Replacing traditional chemical pickling: avoiding the use of strong acids and alkalis, reducing environmental pollution and workpiece corrosion risks, and more in line with environmental requirements.

Pre treatment advantages: Provide clean and active surfaces for subsequent painting (such as spray painting, plating), welding, or assembly, and enhance adhesion.

3、 Surface strengthening and improvement of mechanical properties

Introducing residual compressive stress: The impact of projectiles causes plastic deformation of the surface layer, forming a residual compressive stress layer, which can significantly improve the fatigue strength and stress corrosion cracking (SCC) resistance of pipes. This is particularly important for pipelines that withstand alternating loads such as vibration and pressure fluctuations, such as chemical pipelines and aerospace fittings.

Refining surface grain size: Local plastic deformation can promote surface grain refinement, improve material surface hardness, and enhance wear resistance.

4、 Precise control of surface roughness

Uniform roughened surface: By adjusting the material (such as steel shot, ceramic shot), particle size, spray pressure, and angle of the pellets, the surface roughness (Ra value) can be precisely controlled to meet different working conditions:

High roughness: suitable for scenarios where coatings (such as anti-corrosion coatings) need to adhere, increasing mechanical bite effect;

Low roughness: Used in situations where high surface smoothness is required (such as food grade pipelines, medical devices), while retaining a certain degree of anti slip performance.

Eliminating processing marks: Covering the mechanical processing patterns on the surface of the pipe (such as rolling marks and scratches) to make the appearance more uniform and consistent.

5、 Flexible process and high cost-effectiveness

Strong adaptability: It can handle stainless steel pipes of different specifications (diameter, wall thickness), including straight pipes, bent pipes, complex fittings, and even inner walls (through specialized equipment).

Efficient batch processing: Compared to manual polishing or electrochemical treatment, shot blasting has higher efficiency and is suitable for industrial batch production, reducing labor costs.

Low risk of damage: By adjusting parameters such as pressure and projectile velocity, deformation or thinning of the pipe caused by excessive impact can be avoided, especially for thin-walled pipes.

6、 Environmental and safety advantages

Dry physical process: No chemical solution required, reducing wastewater and exhaust emissions, in line with modern green manufacturing requirements.

No risk of hydrogen embrittlement: Unlike electroplating and other processes that may introduce hydrogen atoms, shot peening has no hidden danger of hydrogen embrittlement and is suitable for high-strength stainless steel materials.

7、 Improve dimensional accuracy

Micro deformation control: The impact force of the projectile is uniform, with little impact on the size, suitable for precision stainless steel pipes (such as hydraulic cylinders and instrument pipelines).

Typical application scenarios

Industrial pipelines: chemical, petroleum, and natural gas pipelines to enhance corrosion resistance and fatigue life;

Aerospace: Engine piping, hydraulic system fittings, enhanced resistance to vibration and stress corrosion;

Medical equipment: Medical stainless steel tubes (such as endoscope tubes), clean the surface and control roughness to meet hygiene standards;

Decoration field: Stainless steel pipes for architectural decoration (such as railings and handrails), giving a uniform matte texture or anti slip effect.

summarize

Shot peening treatment of stainless steel pipes achieves multiple effects of surface cleaning, strengthening, and roughening through physical impact, combining process flexibility and performance improvement advantages. It is an important means of optimizing the comprehensive performance of stainless steel pipes in modern manufacturing. In practical applications, it is necessary to select the appropriate type of projectile and process parameters based on the purpose, material characteristics, and subsequent processes of the pipe to achieve the best results.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More