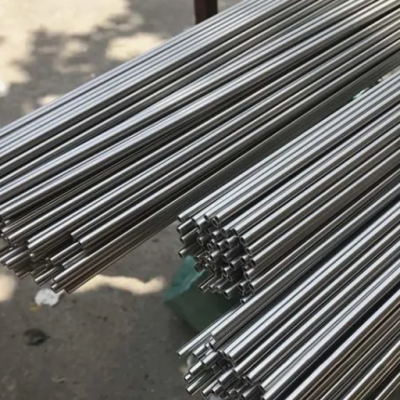

How is the dimensional tolerance of the stainless steel pipes for the Sichuan-Tibet Railway project

The strict control of the dimensional tolerances of stainless steel pipes in the Sichuan-Tibet Railway project requires the realization through the collaborative technology and meticulous management of the entire industrial chain. Based on industry practices and engineering requirements, specific safeguard measures can be elaborated from the following aspects:

1. Full-process control of production process

Equipment accuracy and process optimization

Cold rolling / cold drawing process: A closed-loop hydraulic AGC system (automatic thickness control) is adopted. By monitoring the rolling force in real time and adjusting the gap between the rolls, the wall thickness tolerance can be stabilized within the range of ±0.05mm. The laser alignment instrument is combined with a hydraulic fine-tuning device with an accuracy of 0.001mm, which enables the coaxiality error of the rolls to be controlled within 0.005mm, and the ellipticity to be reduced from 0.8% to below 0.3%.

Seamless pipe manufacturing: During the piercing process, the conical roller piercing machine heats the billet at 1200℃, combined with the multi-pass rolling of the automatic tube rolling unit, ensures the uniformity of the wall thickness. The sizing machine uses a conical drill with high-speed rotation to precisely control the inner diameter size, with an error of ≤±0.1mm.

Welding process: Promote automated technologies such as plasma welding and laser welding, replacing manual argon arc welding. The weld bead height is ≤0.5mm, and the undercut depth is ≤0.1mm. After welding, a combination process of mechanical polishing + electrolytic polishing is adopted, making the gloss difference between the weld zone and the base material ≤10%, and eliminating local deformation.

Heat treatment and surface treatment

During the solution treatment, the rapid temperature rise is to 1050-1150℃, and the holding time is strictly controlled (calculated based on the pipe wall thickness, 1.5 minutes/mm). Then, water quenching is carried out for cooling to prevent the formation of carbides, which may cause dimensional changes.

The acid washing adopts a three-stage process (pre-acid washing - main acid washing - passivation), with the acid solution concentration gradient controlled at 5%-15%-3%, avoiding excessive corrosion that may cause wall thickness thinning. The surface cleanliness reaches Sa2.5 grade.

II. Real-time Online Detection and Intelligent Monitoring

Multidimensional Detection Technology

Outer Diameter and Ellipticity: The dual-channel diameter measuring instrument uses two sets of vertically arranged photoelectric sensors to measure the bidirectional outer diameter of the stainless steel pipe in real time, with an accuracy of ±0.02mm. It simultaneously calculates the non-circularity and gives an audible and visual alarm when the measurement exceeds the limit.

Wall Thickness Measurement: The ultrasonic thickness measuring instrument, combined with the eddy current detector, achieves high-precision measurement of the wall thickness of ±0.05mm, especially suitable for thin-walled pipes (with a wall thickness of ≤2.0mm).

Length Control: The laser distance measuring instrument works in conjunction with the servo control system, achieving a cutting accuracy of ±0.5mm for fixed-length cutting, solving the problem of size deviations in long pipes (such as 12m).

Full Process Data Traceability

The MES system records information such as the raw material batch, rolling parameters, and test results of each steel pipe, generating a unique QR code identifier to enable traceability of quality issues to specific workstations and operators. For example, a certain enterprise used this system to reduce the surface defect rate of raw materials from 3% to 0.5%.

III. Quality Control System and Standard Compliance

Third-party Testing and Certification

The Sichuan-Tibet Railway project requires suppliers to provide test reports issued by authoritative institutions such as China Steel Quality Inspection, covering chemical composition analysis (such as 18%-20% Cr and 8%-10.5% Ni in 304 stainless steel), mechanical performance tests (tensile strength ≥ 520 MPa), and non-destructive testing (ultrasonic, magnetic particle detection). Each batch of products must pass a 720-hour neutral salt spray test to verify the corrosion resistance of the surface passivation film.

Standard Collaboration and Customization

Refer to international standards such as GB/T 14976-2012 "Stainless Steel Seamless Pipes for Fluid Transportation" and ASTM A312, and customize "precision grade" tolerance requirements for the special needs of the Sichuan-Tibet Railway (such as high coldness and high altitude). For example, for steel pipes with an outer diameter of ≥ 168.3mm, the allowable deviation is ±0.75% D (D is the nominal outer diameter), and the dimensional stability is verified through pressure cycling tests (1.5 times the rated pressure).

IV. Precise Control during Construction and Installation

Transportation and Storage Protection

The steel pipes are stacked layer by layer using special supports to prevent deformation caused by stacking and squeezing; during transportation, elastic buffer materials are used for isolation to prevent collision damage. The storage environment should be dry and well-ventilated, and away from corrosive substances.

Installation Process Specifications

Cutting and Assembly: Use mechanical cutting (such as CNC plasma cutting machines) to ensure that the cutting edge has a perpendicularity of ≤ 0.5mm, avoiding dimensional distortion caused by hot processing. Before assembling the weldments, remove oil stains and burrs within a 10mm range on the inner and outer surfaces to ensure uniform gaps.

Connection and Support: When connecting thin-walled stainless steel pipes with other materials, use special conversion connection pieces (such as threads or flanges) to prevent electrochemical corrosion. The spacing of the supports is adjusted according to the pipe diameter (for example, the spacing for DN100 pipes should be ≤ 3m) to avoid bending caused by self-weight.

Pressure Test: After installation, conduct a water pressure test at 1.5 times the working pressure, with a holding time of ≥ 30 minutes. Combine with endoscopy flaw detection to inspect the internal quality of the welds to ensure no leakage or deformation.

V. Environmental Adaptability Design and Material Upgrade

Material Selection

For the high-altitude and strong ultraviolet environment in Xizang, 316L or 2205 duplex stainless steel is preferred. The Mo content (2%-3%) of 316L enhances its resistance to chloride ion corrosion, and the high strength (yield strength ≥ 450 MPa) of 2205 duplex steel reduces the dimensional fluctuations caused by temperature changes.

Structural Optimization

During the design stage, a tolerance margin of 0.5%-1% is reserved to compensate for the thermal expansion and contraction caused by the day-night temperature difference (up to 30°C) in high-altitude areas. For example, long-distance pipelines use "Ω" type compensators to absorb axial displacement and avoid excessive stretching or compression.

VI. Technological Innovation and Continuous Improvement

Intelligent Inspection Equipment

Introduce an AI visual inspection system, which uses CCD cameras to identify surface scratches, holes, and other defects. The detection speed reaches 30 meters per minute, with an accuracy rate exceeding 99%. Digital twin technology simulates size changes under different working conditions to optimize production parameters in advance.

Collaboration between Industry, Academia, and Research

Collaborate with universities to develop "Special Steel for Sichuan-Tibet Railway". Through micro-alloying (such as adding Nb and Ti), the grain size is refined, enhancing the material's resistance to deformation. A certain enterprise has reduced the surface defect rate of raw materials from 3% to 0.5% through this technology.

Conclusion

The dimensional tolerance control of stainless steel pipes in the Sichuan-Tibet Railway project is a comprehensive manifestation of material science, manufacturing technology, testing techniques and engineering management. Through multi-dimensional measures such as upgrading equipment accuracy, optimizing process parameters, conducting full-process testing, and designing environmental adaptability, combined with strict quality traceability and third-party certification systems, the dimensional deviation of the stainless steel pipes can be ensured to be stable within the range of ±0.5mm (outer diameter) and ±10% S (wall thickness), providing a solid guarantee for the safe operation of the plateau railway.

Recently Posted

-

What are the specific measures for controlling the polishing cracks of stainless steel welded pipes

December 31, 2025To control the polishing cracks of stainless steel pipes, measures should be taken from multiple dimensions including material sel Read More

Read More -

What are the main manufacturing processes used for producing high-pressure resistant stainless steel

December 31, 2025The manufacturing process of high-pressure-resistant stainless steel pipes needs to take into account the material strength, dimen Read More

Read More -

What are the key features of BA grade stainless steel pipe?

December 31, 2025BA grade stainless steel pipe (Bright Annealed stainless steel pipe) is a high-precision stainless steel pipe that has undergone b Read More

Read More -

What is the purpose of sandblasting treatment for 201 stainless steel welding pipes

December 31, 2025201 The main purpose of sandblasting treatment for stainless steel welded pipes is to achieve surface cleaning, strengthening, and Read More

Read More