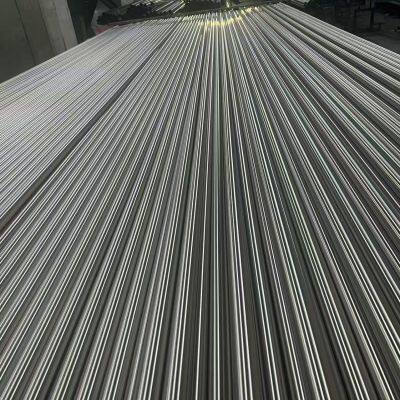

The benefits of acid washing treatment for stainless steel pipes

The acid washing treatment of stainless steel pipes has the following benefits:

Removing oxide scale: During the processing or under high-temperature conditions, stainless steel surfaces will form oxide scale. Acid washing can effectively remove this layer of oxide scale, revealing a bright metal surface. For example, after hot rolling of stainless steel pipes, through acid washing, the hard oxide scale on the surface can be quickly removed, providing a good foundation for subsequent processing.

Improving corrosion resistance: Acid washing can make the chromium elements on the surface of stainless steel pipes fully exposed and form a passivation film. This layer of passivation film can effectively isolate the metal from the contact with external corrosive media, enhancing the corrosion resistance of stainless steel pipes. For instance, after acid washing treatment, stainless steel water pipes can better resist corrosion from impurities and acids and bases during long-term use.

Improving appearance quality: Acid washing can remove impurities such as oil stains and rust spots on the surface of stainless steel pipes, making the surface smoother and more flat, thereby improving the appearance quality of the product. For some stainless steel pipes used in decorative fields, such as architectural decoration lines and furniture decorative parts, the good appearance after acid washing treatment can directly meet the decoration requirements, without the need for extensive surface modification treatments.

Facilitating subsequent processing: The surface of stainless steel pipes after acid washing is clean and has uniform roughness, providing a good foundation for subsequent processing procedures, such as electroplating, painting, welding, etc. For example, during electroplating, acid washing treatment can increase the surface activity of stainless steel pipes, making the coating bond more firmly with the base, thereby improving the electroplating quality.

Detecting internal defects: Acid washing can make minor cracks, pores, and other defects on the surface of stainless steel pipes more obvious, facilitating the detection of these defects through visual inspection or other detection methods, thereby ensuring product quality. For example, when inspecting stainless steel seamless pipes for quality, acid washing treatment can help inspectors more accurately determine whether there are defects inside the pipe material.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More