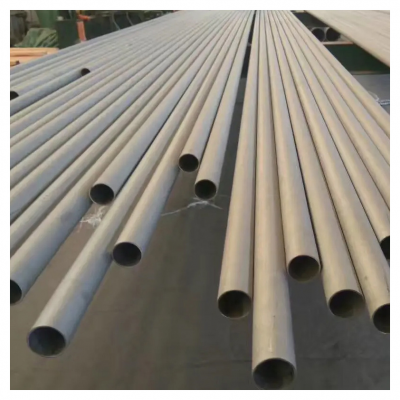

Today, let's introduce some precautions for storing stainless steel pipes

1. Select an appropriate site and warehouse: The site or warehouse where stainless steel pipes are stored should be located in a clean and well-drained area, far away from factories or mines that produce harmful gases or dust. The site should be free of weeds and other debris, and the steel should be kept clean; the warehouse should not store materials such as acids, alkalis, salts, and cement that are corrosive to stainless steel pipes; different types of stainless steel pipes should be stored separately to prevent confusion and corrosion contact; the warehouse should be well-ventilated on sunny days and sealed against moisture on rainy days, and the storage environment should be maintained in an appropriate state frequently.

2. Proper stacking and first-in-first-out principle: The stacking principle requires that, under the condition of stable stacking and ensuring safety, materials should be stacked by type and specification. Different types of materials should be stacked separately to prevent confusion and mutual corrosion; items that are corrosive to steel are prohibited from being stored near the stack position; the bottom of the stack should be elevated, solid and flat to prevent materials from getting damp or deformed; the same type of materials should be stacked separately according to the order of entry into the warehouse to facilitate the implementation of the first-in-first-out principle; for steel sections stored outdoors, wooden pads or stone slabs must be placed under them, the stack surface should be slightly inclined to facilitate drainage, and attention should be paid to placing the materials straight to prevent bending and deformation; for angle steel and channel steel stored outdoors, they should be placed upside down, that is, the opening facing down, I-beams should be placed upright, and the I-shaped surface of the steel should not face upwards to avoid water accumulation and rusting.

3. Packaging and protective layers for the protective materials: The anti-corrosion agents or other coatings and packaging applied to the stainless steel pipes before leaving the factory are repeated measures to prevent material corrosion. During transportation and handling, care must be taken to protect the materials and prevent any damage, which can extend the storage period of the materials.

4. Maintain the cleanliness of the warehouse and enhance material preservation: When storing steel pipes, it is necessary to prevent them from being exposed to rain or contaminated with impurities. For materials that have been exposed to rain or contaminated, different methods should be used to clean them according to their properties. For example, for hard materials, a steel wire brush can be used; for soft materials, cloth or cotton can be used. For stainless steel pipes, regular inspections should be conducted after. If there is rust, the rust layer should be removed. Generally, after cleaning the surface of ordinary steel, no oil needs to be applied. However, for high-quality steel, alloy thin steel plates, thin-walled stainless steel pipes, and alloy steel pipes, after desalination, both the inside and outside surfaces need to be coated with anti-rust oil before storage. For stainless steel pipes with severe rust, for example,

Recently Posted

-

How to prevent white marks from appearing after the acid washing and passivation of stainless steel

January 13, 2026To prevent white marks from appearing on stainless steel pipes after acid pickling and passivation, it is necessary to control the Read More

Read More -

What are the relevant standards for stainless steel welded pipes

January 13, 2026Standard for Stainless Steel Welded PipesI. Chinese National Standards (GB/T)GB/T 12771-2019 "Stainless Steel Welded Pipes fo Read More

Read More -

What is a stainless steel capillary tube

January 13, 2026A stainless steel capillary tube is a slender stainless steel tube made of stainless steel material. Stainless steel capillary tub Read More

Read More -

Today, I'd like to share with you the differences between "stainless steel pipe polishing, sandblast

January 13, 20261. Sandblasted finish: This is actually the original color of stainless steel. The surface has no grainy texture. Its characterist Read More

Read More