What are the environmental impacts of the degreasing process for deoxidized stainless steel pipes?

The environmental impact of the degreasing process for deaerated stainless steel pipes mainly lies in aspects such as pollutant emissions, resource consumption, and waste disposal. The degree of this impact is closely related to the type of degreasing process (such as chemical degreasing, solvent degreasing, electro-degreasing, etc.) and the implementation of environmental protection measures. The following analysis is conducted from different links and potential impacts:

I. Main environmental impact aspects of degreasing process

1. Degreasing agent usage and discharge

Chemical degreasing (alkaline degreasing agent):

If alkaline solutions (such as sodium hydroxide, sodium carbonate) are discharged directly without treatment, they will cause an increase in water pH, damaging the aquatic ecosystem and affecting the survival of fish and microorganisms;

Some degreasing agents contain phosphates (such as trisodium phosphate), which may cause water body eutrophication, leading to excessive algae growth.

Solvent degreasing (organic solvents):

Common solvents such as trichloroethylene, carbon tetrachloride, and acetone are volatile and can form VOCs (volatile organic compounds) emissions, polluting the atmosphere and participating in photochemical smog reactions;

Trichloroethylene and other solvents are toxic. If they leak or are not properly treated, they will pollute the soil and groundwater, and their biodegradability is poor, possibly accumulating in the ecosystem.

Electrode degreasing:

During the electrolysis process, a small amount of harmful gases (such as chlorine gas, hydrogen gas) may be produced. If not effectively collected, they will pollute the workshop air or be discharged into the atmosphere;

Electrolyte waste may contain heavy metal ions (such as heavy metal complexing agents added in the degreasing agent), and if not properly treated and discharged, it will cause heavy metal pollution in the soil.

2. Cleaning wastewater and waste

Cleaning process: After degreasing, a large amount of water is needed for rinsing. If oily wastewater is directly discharged, the oil will form an oil film on the water surface, hindering oxygen dissolution and causing oxygen deficiency for aquatic organisms;

Solid waste: The oil stains, metal debris, and the mixture of degreasing agent generated during degreasing belong to hazardous waste (such as HW06 organic solvent waste, HW49 other waste). If they are randomly discarded, they will pollute the soil and groundwater.

3. Energy and resource consumption

Heating energy consumption: Chemical degreasing often requires heating (such as 60-80℃) to improve efficiency, consuming electricity or heat energy, and increasing carbon emissions;

Water resource consumption: If the recycling cleaning system is not designed properly, it will result in a large amount of fresh water usage, especially in water-scarce areas, exacerbating water resource tension.

II. Comparison of Environmental Impacts of Different Degreasing Processes

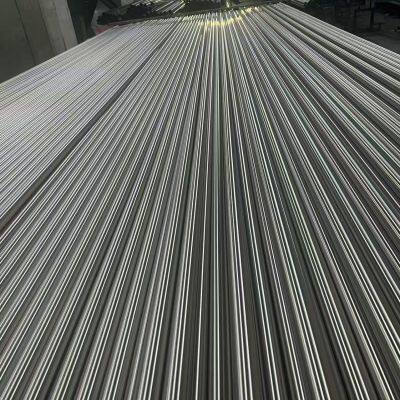

Picture 1

III. Control of Environmental Impact and Environmental Protection Measures

1. Source Reduction

Replacement of Degreasing Agents:

Use environmentally friendly degreasing agents, such as phosphorus-free alkaline degreasing agents and biodegradable surfactants (such as alkyl glycosides APG), to reduce the emission of phosphates and toxic substances;

Promote water-based degreasing agents or supercritical CO₂ degreasing (utilizing the supercritical state of CO₂ to dissolve oil, without VOCs emissions, and recyclable).

Optimize Process Parameters:

Reduce degreasing temperature (such as using low-temperature efficient degreasing agents), shorten processing time, and reduce energy consumption;

Use a closed-loop degreasing system, through filtration and regeneration technologies, to extend the service life of degreasing agents and reduce the amount of waste liquid.

2. Process Control

Waste Gas Treatment:

Set up sealed hoods and activated carbon adsorption devices in solvent degreasing workshops to capture VOCs and catalytically combust (such as RCO catalytic combustion technology), ensuring that the emission concentration complies with the "Integrated Emission Standard for Air Pollutants" (GB16297);

Set up an exhaust gas collection system in electrolytic degreasing tanks to treat gases such as chlorine and discharge them after meeting standards.

Wastewater Treatment:

Establish a separate treatment system: alkaline degreasing wastewater is first adjusted to neutral pH in a neutralization tank, then removed of oil through air flotation, and finally treated by biochemical processes (such as A/O process) to degrade organic matter;

Solvent degreasing wastewater needs to be first distilled to recover solvents, then treated by activated carbon adsorption or advanced oxidation (such as ozone oxidation) to remove residual organic matter, ensuring that indicators such as COD and BOD meet the "Comprehensive Wastewater Discharge Standard" (GB8978).

3. Terminal Treatment and Recycling

Solid Waste Classification Disposal:

The oil sludge and waste degreasing agents generated during degreasing belong to hazardous waste and need to be handled by qualified units (such as incineration or resource extraction), in accordance with the "Pollution Control Standard for Hazardous Waste Storage" (GB18597);

The sludge generated from cleaning wastewater treatment is dehydrated and safely landfilled or incinerated.

Resource Recycling:

Use counter-flow rinsing technology to increase the reuse rate of water (such as three-stage counter-flow rinsing, with water reuse rate reaching over 80%);

The solvent degreasing agent is regenerated through distillation, rectification, etc., and reused to reduce the purchase of new solvents.

IV. Industry Environmental Standards and Regulatory Requirements

National Standards:

The "Integrated Emission Standards for Air Pollutants" (GB16297) limits the emission concentrations of gases such as VOCs and chlorine;

The "Integrated Emission Standards for Wastewater" (GB8978) stipulates the limit values for indicators such as pH, COD, and petroleum;

The "Standard for Hazardous Waste Identification" (GB5085.1-7) clearly defines the method for determining the hazardous attributes of degreasing waste.

Industry Norms:

The food and pharmaceutical industries need to comply with the "Emission Standards for Water Pollutants from Pharmaceutical Industry" (GB31573) and the "Emission Standards for Water Pollutants from Starch Industry" (GB25461), which have additional requirements for the hygiene indicators of degreasing wastewater (such as total bacterial count);

The EU REACH regulation restricts the use of high-concern substances (SVHC) in degreasers, such as trichloroethylene has been classified as a carcinogen, and the usage amount is strictly controlled.

V. Sustainable Development Trends

Green degreasing technology: Promote low-pollution processes such as ultrasonic + environmentally friendly degreasing agents, plasma degreasing (using plasma bombardment to remove grease without chemical reagents);

Circular economy model: Establish regional centralized treatment centers for degreasing waste liquids, reducing environmental protection costs through large-scale recycling;

Digital monitoring: Use online monitoring systems to track degreasing agent concentrations and wastewater discharge indicators in real time, ensuring the effective operation of environmental protection measures.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More