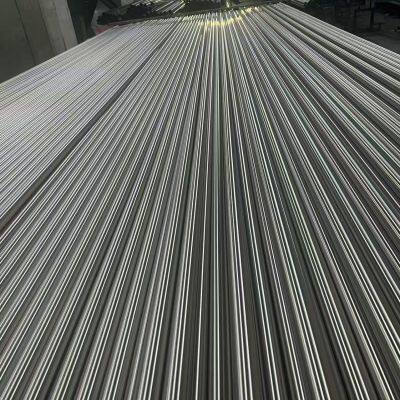

Introduction to degreased stainless steel welded pipes

1、 The core role of degreasing process

1. Clean the surface

Defatting treatment aims to remove contaminants such as grease, lubricants, and metal debris from the surface of stainless steel welded pipes. This process usually includes steps such as pre cleaning, chemical degreasing (using alkaline solutions or environmentally friendly biodegradable agents), high-pressure rinsing, and drying. For precision applications, ultrasonic or plasma degreasing techniques can also be used to ensure extremely high cleanliness of the inner and outer surfaces of the pipeline.

2. Improve welding quality

The degreasing treatment before welding can prevent the decomposition of oil and grease at high temperatures, resulting in porosity or inclusions, ensuring the density and strength of the weld seam. Degreasing after welding is used to remove residual flux during the welding process and prevent corrosion hazards.

3. Protect the passivation layer

The correct degreasing process will not damage the passivation film (chromium rich oxide layer) on the surface of stainless steel, but instead create conditions for subsequent passivation treatment, further enhancing corrosion resistance.

2、 Performance characteristics and industry standards

1. Material and structural advantages

Adopting austenitic stainless steel such as 304 and 316L, it has excellent corrosion resistance, high temperature oxidation resistance, and mechanical strength. The weld has undergone solid solution treatment and online eddy current testing to ensure no defects and is suitable for high-pressure, high-purity environments.

2. Surface quality requirements

According to standards such as ASTM A270, ISO 2037, and GB/T 12771, degreased pipelines must undergo surface tension testing (≥ 32 mN/m), visual inspection, and particle counting testing to ensure that there are no visible contaminants or residual chemicals.

3. Sanitary grade design

The design of inner wall roughness (Ra ≤ 0.8 μ m) and smooth transition of welds (without dents or protrusions) meets the requirements of microbial control in the food and drug industry, and can be used for CIP (online cleaning) and SIP (online sterilization) systems.

3、 Typical application areas

1. Food and beverage industry

Used for conveying pipelines of liquid foods such as dairy products, beer, juice, etc., to ensure that the products are not contaminated. For example, the pipelines of aseptic filling lines need to undergo strict degreasing and passivation to comply with FDA and EU 10/2011 regulations.

2. Pharmaceuticals and Biopharmaceuticals

The pipelines of pharmaceutical equipment, bioreactors, and infusion systems are made of degreased stainless steel welded pipes to prevent the adsorption or degradation of drug active ingredients. Some high-end applications also require electric polishing of the inner wall of the pipeline (Ra ≤ 0.2 μ m).

3. Chemical Industry and Environmental Protection

When transporting corrosive media such as acid and alkali solutions, 316L degreased welded pipes perform well. In environmental protection equipment, it can be used as a high-purity pipeline system for treating wastewater and exhaust gas.

4. Semiconductors and Electronics

The transportation of ultrapure water and high-purity gas requires the use of stainless steel pipes that have undergone electrolytic degreasing and electron beam welding to meet the strict restrictions on particle and metal ion content in SEMI standards.

4、 Market Status and Technological Trends

1. Main manufacturers

Domestic enterprises such as Jiulite Material and Qingshan Steel Pipe, as well as international brands JFE from Japan and ThyssenKrupp from Germany, all have large-scale production capabilities, covering a full range of needs from industrial grade to sanitary grade.

2. Driven by demand growth

With the tightening of global food and drug safety regulations and the expansion of the semiconductor industry, the market for degreased stainless steel welded pipes continues to grow. The global market size is expected to exceed $8 billion by 2024, with a compound annual growth rate of 6.5% over the next five years.

3. Direction of technological innovation

Environmental protection process: Application of biodegradable degreasing agents and low-temperature plasma cleaning technology to reduce chemical pollution.

Intelligent detection: Integrated laser scanning and AI visual inspection system to achieve real-time recognition of surface defects.

Customized service: Provide customized production of pipe diameters (6-600mm), wall thicknesses (0.5-10mm), and special surface treatments (such as matte and mirror finish) according to customer needs.

5、 Selection and usage suggestions

1. Select materials based on the medium

304 stainless steel can be selected for general corrosive environments, while 316L or duplex stainless steel (such as 2205) is required for strong corrosion scenarios.

2. Pay attention to processing technology

Priority should be given to products that use TIG welding and online bright annealing to achieve uniform metallographic structure and optimal corrosion resistance.

3. Verify cleanliness

Require suppliers to provide degreasing treatment reports and third-party testing certificates to ensure compliance with the hygiene standards of the target industry.

Defatted stainless steel welded pipes have become indispensable key components in high-end industrial fields due to their precise manufacturing processes and strict quality control. With the continuous advancement of technology, its application prospects in emerging fields such as new energy and high-end manufacturing will also become broader.

Recently Posted

-

What are the differences between stainless steel pipes and copper pipes?

January 8, 2026Comparison of hygiene performance Stainless steel material is a type of material that can be implanted into the human body. I Read More

Read More -

What are the advantages of thin-walled stainless steel pipes

January 8, 2026Anti-fouling and corrosion-resistant One of the most obvious advantages of thin-walled stainless steel pipes is that they are Read More

Read More -

The main factors influencing the selection of specifications for thin-walled stainless steel pipes

January 8, 2026The properties of the material Stainless steel is a kind of metal material with outstanding mechanical properties, exceptiona Read More

Read More -

How to detect weld defects in stainless steel pipes

January 8, 20261. Welding omission refers to the situation where there are welding points that are not properly welded during the welding process Read More

Read More