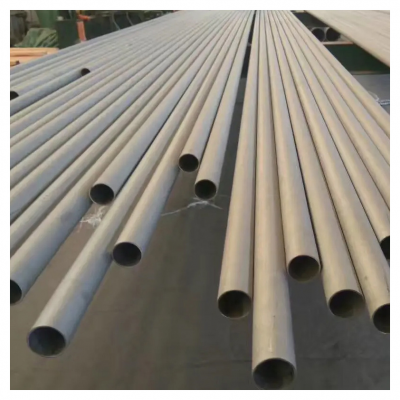

Introduction to 304 Mirror Finish Stainless Steel Tubes!!

I. Market Prospects

With the acceleration of industrialization and modernization, stainless steel pipes, as an important construction and manufacturing material, have seen a year-on-year increase in market demand. Among stainless steel pipes, 304 mirror-finish stainless steel pipes, as the outstanding choice, have witnessed a continuously rising market demand. In recent years, China has been engaged in urban construction and renovation, which requires a large amount of mirror-finish stainless steel materials. Therefore, the market demand for 304 mirror-finish stainless steel pipes will be further enhanced.

In addition, with the rapid development of the domestic economy, the demand for high-quality stainless steel pipe materials has also increased. The 304 mirror-finish stainless steel pipe stands out for its excellent performance and, compared with other materials, it has a good visual effect. Therefore, it is widely used in various fields.

These factors will contribute to the continued growth of the 304 mirror-finish stainless steel pipe market, which has a promising future.

II. Application Domains

The 304 mirror-finish stainless steel tube features excellent corrosion resistance, high temperature strength and excellent forming performance. It is applicable in the following fields:

In the field of architecture: 304 mirror-finish stainless steel tubes are widely used in building facades, interior and exterior decoration, landmark buildings, etc. They have excellent mirror effect, good weather resistance, high gloss, and a beautiful appearance.

2. Chemical Industry: 304 mirror-finish stainless steel pipes play a significant role in areas such as chemical storage and transportation, corrosion-resistant underground pipelines, and oil and gas transportation. Their high strength and excellent corrosion resistance ensure the safe operation of the pipeline transportation system.

3. Manufacturing sector: 304 mirror-finish stainless steel tubes are widely used in precision instruments and mechanical equipment in the manufacturing industry. Their excellent forming performance can provide manufacturers with higher production efficiency.

III. Analysis of Advantages

The 304 mirror-finish stainless steel pipe has the following advantages over traditional steel pipe materials:

1. Excellent corrosion resistance: The 304 mirror-finish stainless steel pipe has outstanding corrosion resistance, capable of withstanding the erosion of most chemical substances, and also possesses excellent high-temperature resistance.

2. Low maintenance cost: The 304 mirror-finish stainless steel tubes do not require frequent painting or film protection. Their surface is naturally smooth and easy to clean, resulting in low maintenance costs.

3. Excellent formability: The 304 mirror-finish stainless steel tube has excellent forming properties, enabling it to meet various shape requirements. It has a lower manufacturing cost and can also reduce waste.

IV. Development Trends

Optimize product structure: With the continuous development of technology, manufacturers have increasingly higher requirements for the quality and details of 304 mirror-finish stainless steel pipes. Therefore, the product structure will be optimized and improved.

2. Expand application fields: The application scope of 304 mirror-finish stainless steel pipes will continue to expand. Through continuous research and development, its application range will be further expanded and extended.

3. Environmental protection and energy conservation: During the production process, new technologies and materials will be adopted, the production process will be optimized, production efficiency will be enhanced, and environmental pollution will be reduced.

V. Summary

The 304 mirror-finish stainless steel pipe, as a kind of stainless steel pipe material with broad application prospects, holds significant value in terms of market potential, application fields, advantages, and development trends. Increasing research and development efforts on it, as well as optimizing production processes, will help expand its application fields and enhance its market prospects.

Recently Posted

-

How to prevent white marks from appearing after the acid washing and passivation of stainless steel

January 13, 2026To prevent white marks from appearing on stainless steel pipes after acid pickling and passivation, it is necessary to control the Read More

Read More -

What are the relevant standards for stainless steel welded pipes

January 13, 2026Standard for Stainless Steel Welded PipesI. Chinese National Standards (GB/T)GB/T 12771-2019 "Stainless Steel Welded Pipes fo Read More

Read More -

What is a stainless steel capillary tube

January 13, 2026A stainless steel capillary tube is a slender stainless steel tube made of stainless steel material. Stainless steel capillary tub Read More

Read More -

Today, let's introduce some precautions for storing stainless steel pipes

January 13, 20261. Select an appropriate site and warehouse: The site or warehouse where stainless steel pipes are stored should be located in a c Read More

Read More