What are the polishing processes for thin-walled stainless steel pipes

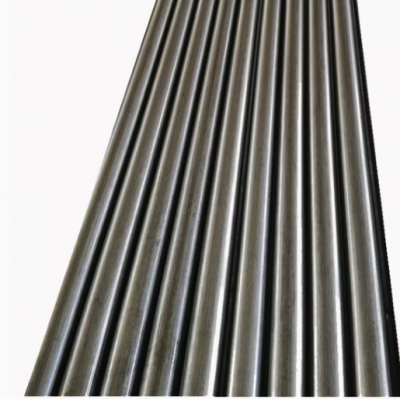

Thin-walled stainless steel water pipes are widely used due to their unique production process and excellent performance. The transportation of drinking water for households cannot be done without the cooperation of stainless steel pipes. However, the production of these pipes cannot be achieved without the polishing process.

Detailed introduction to the polishing process of thin-walled stainless steel water pipes:

The polishing process is actually a procedure for cutting the surface of stainless steel water pipes. Generally, a polishing machine is used, and polishing auxiliary materials come into contact with the surface of the stainless steel pipes for friction, achieving the cutting of the pipe surface and obtaining the corresponding smooth surface.

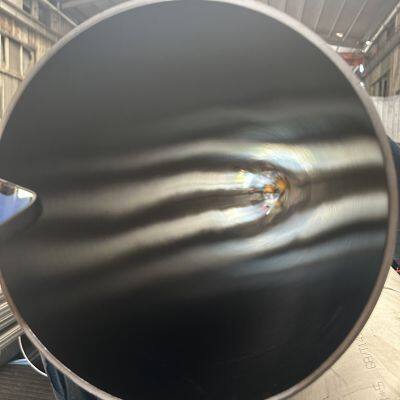

2. The surface finish of stainless steel pipes can also be classified into internal and external finishes. The external finish is achieved by using different coarse-grained jute wheels to cut the surface, resulting in a smooth finish. The internal finish is obtained by using plastic grinding heads inside the stainless steel pipes or by selecting reciprocating motion to cut the interior of the stainless steel pipes.

3. The surface-polished stainless steel water pipes have a very clean and bright appearance, making them easier to clean and maintain. They also form an invisible protective film that can prevent the corrosion of the stainless steel surface and reduce the likelihood of scaling. As a result, their service life is relatively longer than that of unpolished stainless steel pipes.

4. Polishing the thin-walled stainless steel water pipes not only enhances their aesthetic appeal but also increases their usability. This makes them more durable and applicable in a wider range of scenarios.

5. The main characteristics of electrochemical polishing are as follows: The surface of the polished mirror-like stainless steel water pipes has no thermal degradation layer and no additional external stress. There are no requirements for the hardness and effectiveness of the material. It can achieve cleanliness, thereby obtaining a low and thin mirror-like thin-walled stainless steel water pipe surface. It can polish complex small mirror-like thin-walled stainless steel water pipes, with high processing efficiency, short polishing time, small surface treatment volume, high surface quality after polishing, and usually the surface cleanliness can be improved through two steps.

By comparing electrochemical polishing with other common surface polishing techniques, it can be seen that electrochemical polishing has a higher overall score and is thus a relatively good method for surface polishing.

Compared with the common mechanical polishing, electrochemical polishing has the following advantages:

(1) Using electrochemical dissolution, the treatment process is smooth, and the smoothness after polishing can reach a mirror-like effect, including intense processes such as cutting and plastic deformation.

(2) The shape requirements for electrochemical polishing are relatively low. It can achieve mirror-polished treatment for stainless steel tubes, wires, thin plates, and small components with complex structures. Electrochemical polishing has much lower requirements for process and equipment compared to mechanical polishing. However, due to the sharp effect during the electrochemical polishing process, the edges of the polished steel pipes first melt, so sharp edges cannot be polished.

(3) The polishing efficiency of electrochemical polishing is much higher than that of mechanical polishing. It can simultaneously polish multiple components. Moreover, the electrochemical polishing process has good repeatability, simple operation methods, and relatively low dependence on operational skills. During the processing, there is no noise or dust.

Recently Posted

-

How to identify 304 and 201 stainless steel pipes

January 12, 2026The 304 stainless steel water supply pipe has a higher safety factor and stronger performance compared to other water supply pipes Read More

Read More -

How to identify 304 and 201 stainless steel pipes

January 12, 2026The 304 stainless steel water supply pipe has a higher safety factor and stronger performance compared to other water supply pipes Read More

Read More -

How to identify 304 and 201 stainless steel pipes

January 12, 2026The 304 stainless steel water supply pipe has a higher safety factor and stronger performance compared to other water supply pipes Read More

Read More -

How to deal with rust on the outer wall of stainless steel water pipes

January 12, 2026With the continuous improvement of people's living standards, the use of stainless steel water pipes has become increasingly w Read More

Read More