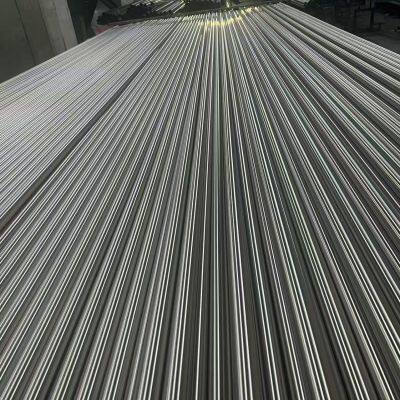

Treatment methods for the oil in the inner hole of seamless steel pipes that is difficult to burn of

I. Problem Description

During the annealing process of seamless steel pipes, due to the application of a certain thickness of grease in the inner hole, it is easy for the grease to be burned off during annealing, forming black carbon substances, which affects the quality of seamless steel pipes.

II. Problem Analysis

The burning off of the inner hole grease is mainly due to the insufficient heat transfer to the inner hole, causing the inner hole temperature to be too high and the grease to be decomposed. Common causes include:

1. The annealing temperature is too high, and the inner hole temperature cannot be kept consistent with the outer surface temperature.

2. The annealing medium is inappropriate, with poor heat conduction or excessive addition of impurities such as iron oxide.

3. The annealing time is too long, causing the grease in the inner hole to be burned off due to continuous heat action.

III. Solutions

1. Adjust the annealing process

To ensure uniform annealing temperature, the following measures can be taken:

(1) Increase the annealing fixtures and inner hole support objects to reduce the impact of internal airflow on the inner hole.

(2) Set up a ceramic membrane to isolate the inner hole, ensuring that the inner hole temperature is consistent with the outer surface temperature during the heating process.

(3) Use pure annealing medium, and it is best to purify the medium before use.

2. Select the appropriate annealing medium

To avoid the burning off of the inner hole grease, a medium with good heat conduction should be chosen. It is recommended to use high-temperature synthetic oil or hydrogenated hydrocarbon substances as the annealing medium. These media have good heat conductivity, can fully transfer heat, prevent heat dissipation on the outer surface, and will not burn off the inner hole grease.

3. Control the annealing time

The annealing time is the key to preventing the burning off of the inner hole grease. Excessive annealing time not only wastes energy but also lowers the decomposition temperature of the inner hole grease, making it easier to be burned off. Therefore, the annealing time should be precisely controlled during the annealing process to achieve the best effect in the shortest time.

IV. Conclusion

Through the above three adjustments, the burning off of the inner hole grease can be effectively avoided, improving the quality of seamless steel pipes. It is necessary to pay attention to safety measures during the annealing process, select appropriate media and reasonable processes, and avoid the occurrence of fires and other dangers. At the same time, in actual production, there should be corresponding detection measures, and products that do not meet quality standards should be eliminated to ensure product quality.

Recently Posted

-

Why is it not recommended to use 304 material for bolts

January 19, 2026(1) What are the basic differences among 304, 304L, 316, and 316L materials?304, 304L, 316, and 316L are the common types of stain Read More

Read More -

The Importance of Pre-Weld Heating and Post-Weld Heat Treatment

January 19, 20261. Pre-weld heatingPre-weld heating and post-weld heat treatment are of great significance for ensuring welding quality. For weldi Read More

Read More -

What are the differences between stainless steel pipe polishing, sandblasting and sanding

January 19, 2026The following explains the differences between the processes of wire polishing, sandblasting and sandblasting for stainless steel Read More

Read More -

The application fields of large hydraulic pipes

January 19, 2026I. Construction Machinery FieldIn the construction machinery field, large hydraulic pipes are widely used in concrete pumpers, con Read More

Read More