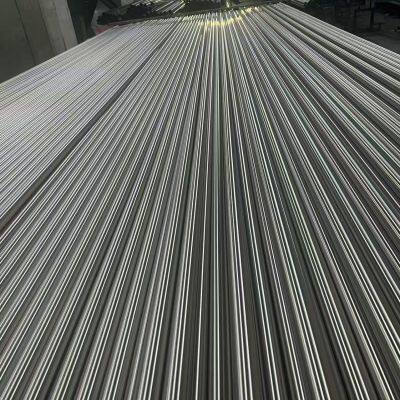

How to Install Thin-Walled Stainless Steel Pipes

Thin-walled stainless steel pipes have been widely used in households and industries in recent years due to their light weight, corrosion resistance and high strength. However, many people are not familiar with the installation process, which often leads to unnecessary troubles and costs. This article will provide you with a detailed installation guide for thin-walled stainless steel pipes to ensure that you can complete the installation smoothly and guarantee the long-term stability of the pipeline system.

I. Advantages of Thin-Walled Stainless Steel Pipes

Before delving into the installation steps, let's take a look at the advantages of thin-walled stainless steel water pipes:

1. Strong corrosion resistance: The stainless steel material makes it less likely to rust under the influence of water quality changes and the environment, making it particularly suitable for drinking water systems.

2. Lightweight and portable: The thin-walled design reduces the weight of the pipe, making it easier to handle and install.

3. High strength: Despite its relatively thin wall thickness, it has excellent compressive and tensile strength, capable of effectively withstanding high water pressure.

4. Poor thermal conductivity: Stainless steel has a relatively low ability to conduct heat, which can effectively reduce the condensation on the surface of water pipes.

5. Environmentally friendly materials: Stainless steel is recyclable and in line with modern environmental protection concepts.

II. Preparation of Installation Tools and Materials

Before starting the installation, let's prepare the necessary tools and materials first:

Tools:

Measuring tools: tape measure, line gauge, etc.

Cutting tools: pipe cutter or saw.

Connectors: Various specifications of couplings, elbows, tees, etc.

Fixed equipment: pipe clamps, screws, etc.

Sealing materials: raw material tape, sealant, etc.

Auxiliary tools: safety equipment such as gloves and goggles.

Material:

Thin-walled stainless steel water pipes: Select the appropriate length and diameter as needed.

Connection fittings: Ensure that the connecting parts match the pipes.

Anti-corrosion coatings: In some special environments, additional anti-corrosion coatings can be used for surface treatment.

III. Detailed Installation Steps

On-site measurement and planning

Before starting the installation, it is necessary to conduct thorough measurements of the installation environment and plan the layout of the water pipes. This includes:

Pipeline routing: Confirm the pipeline's routing to avoid unnecessary bends or obstructions in the later stage.

Location of water source: Ensure that the connection point between the water source and the pipeline is clear for easy access in the future.

Landing position: If it is necessary to fix the pipe to the wall or the ground, make sure there is an appropriate fixing position and space.

2. Pipe Cutting

Based on the measurement results, use a pipe cutter or saw to cut the water pipe to the required length. When cutting, pay attention to:

- Neat edges: The cut edges should be smooth and flat, avoiding any burrs.

Safety operation: During the cutting process, be sure to wear protective goggles and gloves, and pay attention to the safety of the cutting tools.

3. Connect the pipes

According to the planned pipeline route, connect each section of the pipeline one by one. When connecting, pay attention to the following points:

- Use of connectors: Ensure that the connectors used match the pipe diameter and are securely connected.

Apply sealant: Apply an appropriate amount of Teflon tape or sealant at the connection point to ensure there is no leakage.

Fixed position: Use pipe clamps to secure the pipes to the wall or floor to ensure they are stable.

4. Inspection and Testing

After all the pipe connections are completed, a system check and test are required.

Check for leaks: Inspect each connection one by one for leaks. If necessary, use soapy water.

Pressure test: Gradually increase the water pressure with caution, observe whether the pipeline can withstand it. If any abnormality is found, make timely adjustments.

5. Protective Measures

To prevent any problems with the pipeline in the future, it is recommended that protective treatment be carried out on the outer layer of the pipeline.

Apply anti-corrosion coating: In environments where corrosion is likely, apply anti-corrosion coating to enhance the service life of pipelines.

Regular inspection: Set up a regular inspection plan to identify problems in a timely manner and prevent large-scale damage.

IV. Common Problems and Solutions

Even if you follow the above steps to install, you may still encounter some problems from time to time. Here are some common issues and their solutions:

Leakage issue: Check the leakage point. It might be due to the uneven application of the sealant. Re-treatment is required.

Insufficient water pressure: Check if the pipes are bent or clogged. If necessary, re-plan the pipe routing.

Pipe deformation: It may be caused by excessively high or low water pressure. Check and adjust the water pressure.

V. Conclusion

Although the installation process of thin-walled stainless steel water pipes is slightly complex, as long as you follow the above steps carefully and pay attention to every detail, you can effectively complete the installation task. Through correct installation, you will have a durable and efficient water pipe system to serve the daily water needs of your family.

We hope this installation guide will be of great help to you and enable you to enjoy the convenience brought by the thin-walled stainless steel water pipes without any worries!

Recently Posted

-

Why is it not recommended to use 304 material for bolts

January 19, 2026(1) What are the basic differences among 304, 304L, 316, and 316L materials?304, 304L, 316, and 316L are the common types of stain Read More

Read More -

The Importance of Pre-Weld Heating and Post-Weld Heat Treatment

January 19, 20261. Pre-weld heatingPre-weld heating and post-weld heat treatment are of great significance for ensuring welding quality. For weldi Read More

Read More -

What are the differences between stainless steel pipe polishing, sandblasting and sanding

January 19, 2026The following explains the differences between the processes of wire polishing, sandblasting and sandblasting for stainless steel Read More

Read More -

The application fields of large hydraulic pipes

January 19, 2026I. Construction Machinery FieldIn the construction machinery field, large hydraulic pipes are widely used in concrete pumpers, con Read More

Read More